7 Trends Reshaping Supply Chain as we know in 2024

7 Trends Reshaping Supply Chain as we know in 2024

The once-invisible arteries of commerce are morphing into a marvel of technology and data. The humble supply chain, long plagued by inefficiencies and blind spots, is undergoing a revolutionary metamorphosis in 2024. At the helm of this change is a potent cocktail of cutting-edge technology – generative AI, automated planning, data-driven insights, and more – promising a future where transparency, resilience, and value flourish. This isn’t just a tech upgrade; it’s a complete rewiring of how we manage the flow of goods, a seismic shift with ripples felt across industries and economies. This blog uses insight published by KPMG

Let’s dive deeper into the specific trends shaping this great supply chain transformation;

Trend #1 – Generative AI

Forget fancy software wizards. GenAI is about injecting your supply chain with serious analytical muscle. Think of it as a data-hungry beast that devours information, learns your company’s unique rhythms, and spits out actionable insights to improve everything from procurement to production. It’s not about magic tricks, it’s about crunching massive data sets to predict problems before they bite you in the wallet.

Actionable Tips –

- Map the pain points – Identify specific areas where GenAI can tackle your biggest supply chain headaches, like late deliveries or inaccurate forecasts.

- Level up your data crew – Don’t expect GenAI to work with dusty spreadsheets. Invest in cleaning up your data mess and training your team to feed the beast the right information.

- Baby steps for big gains – Start small with pilot projects to test the waters. Once you see GenAI’s magic, you can scale up and automate like a champ.

Trend #2 – AI-Powered Planning

No more flying blind with guesswork and crossed fingers. Low-touch planning powered by AI is like having a crystal ball for your supply chain. It churns through complex scenarios, predicts demand fluctuations, and tells you exactly how much stuff you need to make, where to store it, and how to get it to customers without breaking the bank. No more late nights with Excel spreadsheets – AI takes the wheel and gives you time to focus on the big picture.

Actionable Tips –

- Train your planning team – Teach your folks how to interpret AI outputs and translate them into actionable plans. Data literacy is key to unlocking the full potential of this tech.

- Goals, not gadgets – Don’t let AI technology dictate your strategy. Set clear performance goals first, then let AI find the most efficient path to achieve them.

- Data is king, quality is queen – Garbage in, garbage out. Make sure your data is clean, consistent, and readily available before letting AI loose on it.

Trend #3 – Data

Your supply chain is drowning in a sea of data, but most of it sits there like forgotten treasure in a dusty attic. The key is to stop hoarding and start using. Focus on specific goals, collect data that actually matters, and clean it up so it’s fit for AI’s discerning palate. Once you do, you’ll unlock insights that can optimize inventory, predict equipment failures, and even spot opportunities for new products.

Actionable Tips –

- Focus on the prize – Don’t just collect data for the sake of it. Identify specific problems you want to solve and gather data that directly addresses them.

- Cleanliness is next to godliness – Dirty data is useless data. Invest in quality checks and data governance to ensure your information is reliable and consistent.

- Small steps, big leaps – Start with one or two data-driven projects to prove the concept. Once you see the results, you can scale up and transform your entire operation.

Trend #4 – Transparency Beyond Tier 1 & Tier 2

You can’t manage what you can’t see. That’s why extending your visibility beyond your immediate suppliers is like turning on the lights in a darkroom. Control tower technology and digital twins give you a panoramic view of your entire supply chain ecosystem, from raw material sourcing to final delivery. This means you can spot hidden risks, identify unethical practices, and even trace the carbon footprint of your products.

Actionable Tips –

- Partners in crime – Don’t go it alone. Collaborate with suppliers and industry partners to share data and build a clearer picture of your extended supply chain.

- Cross-functional teams – Break down the silos and bring together procurement, sustainability, and logistics teams to make the most of your newfound visibility.

Trend # 5 – Low-code platforms

Forget clunky custom software projects that take months and leave you chained to IT. Low-code platforms are a game-changer, letting business users (even those with limited coding skills) build apps that streamline your supply chain in real-time. Imagine automating purchase orders, tracking shipments with live data, or building custom dashboards showing exactly where your inventory is – all without waiting for months and praying the code compiles. These platforms are pre-loaded with integrations and APIs, letting you connect your previously siloed systems like Lego blocks. Low-code isn’t just a tech perk, it’s a mindset shift – empowering your team to react to disruptions, adapt to new strategies, and build an agile, resilient supply chain that fits your specific needs.

Action steps for 2024 –

- Map your pain points – Identify repetitive tasks or clunky processes causing bottlenecks. These are prime candidates for automation.

- Build basic, iterate fast – Start small with simple apps you can build quickly. See the value, then scale up from there.

- Empower your business users – Give them the tools and training to become your internal supply chain app-building superheroes.

Trend # 6 – ESG and Scope 3 emissions

Remember when sustainability was just about recycling paper? Those days are over. Scope 3 emissions – the hidden carbon footprint lurking in your entire supply chain – are now under the spotlight. Governments are mandating reporting, investors are demanding action, and customers are choosing eco-conscious brands. But tracking all those emissions across countless suppliers is a tangled mess.

Action steps for 2024 –

- Start with your biggest spenders – Prioritize suppliers contributing the most to your carbon footprint. Get them on board with data sharing and emissions reduction goals.

- Invest in carbon accounting tools – Ditch the spreadsheets and manual estimations. Cloud-based platforms simplify data collection and analysis, giving you a clear picture of your supply chain’s true environmental impact.

- Educate and collaborate – Train your team on Scope 3 and involve them in finding creative solutions. Work with sustainable suppliers and reward their efforts.

Trend # 7: Electric vehicles, transport, and logistics

Forget gas-guzzling trucks and warehouse workers running around like headless chickens. The future of logistics is electric, automated, and data-driven. Imagine self-driving delivery vans zipping through city streets, robots efficiently picking and packing orders in smart warehouses, and AI optimizing routes in real-time to save time and fuel. Sustainability meets efficiency – a win-win for your business and the planet.

Action steps for 2024

- Assess your fleet – Analyze your transportation needs and identify suitable routes for electrification. Start with short-distance urban deliveries first.

- Embrace automation – Look for opportunities to automate tasks in your warehouses and distribution centers. Free up your humans for higher-value work.

The future is no longer a distant horizon; it’s knocking on your warehouse door. The question isn’t if you’ll embrace these trends, but how quickly and effectively you do. Those who hesitate will find themselves at the mercy of disruption, while those who lead the charge will shape a future of seamless flow, resilience, and responsible value creation.

Understanding Bharat Mart.

Understanding Bharat Mart.

India’s trade ambitions just got a major boost with the proposed “Bharat Mart” in the United Arab Emirates. This ambitious project, envisioned as a one-stop shop for Indian exports, mirrors China’s successful Dragon Mart and promises to revolutionize how Indian businesses reach global markets.

Why Bharat Mart is a game-changer?

l Unified platform: Imagine a sprawling 100,000 square meter complex housing everything from retail showrooms to warehouses, showcasing Indian products in all their glory. Bharat Mart offers a single destination for international buyers, eliminating the need to scramble through multiple vendors.

l Strategic location: Nestled in Dubai’s Jebel Ali Free Zone, Bharat Mart taps into the UAE’s logistical prowess and acts as a gateway to the Middle East, Africa, and Europe – markets teeming with potential for Indian exporters.

l Efficiency and cost savings: Time and money saved, that’s Bharat Mart’s promise. By streamlining logistics and consolidating operations, Indian businesses can cut down on transportation costs and reach buyers faster.

l Digital edge: Bharat Mart envisions a digital platform alongside the physical facility, allowing global buyers to browse and purchase Indian goods at their fingertips. This omnichannel approach caters to modern buying habits and expands reach even further.

l India-UAE synergy: As part of the ambitious CEPA agreement, India and the UAE aim to double non-oil trade to $100 billion by 2030. Bharat Mart is a powerful tool to achieve this goal, boosting Indian exports and strengthening economic ties.

Beyond the benefits, there are exciting possibilities:

l Brand showcase: Bharat Mart can become a brand recognition hub for Indian companies, enabling them to establish themselves in new markets.

l Job creation: This initiative has the potential to generate employment opportunities in both India and the UAE, benefiting both economies.

l Innovation boost: The sheer scale and focus on efficiency can inspire further innovation in India’s export sector.

While still in its developmental stage, Bharat Mart holds immense promise for businesses in India and in the UAE. It’s a bold step towards claiming a larger share of the global market and a testament to India’s growing ambitions. From perishables to heavy machinery, get ready to see “Made in India” proudly displayed on a global stage.

The Bharat Mart will be a significant step forward in the bilateral trade ties of the nations. And manufacturers and exporters in the UAE and India alike can benefit from access to a bigger and more diversified market, profitable strategic partnerships, and sharing of tech initiatives and innovations. A future focused organization like Moglix with its tech led B2B supply chain ecosystem can play a pivotal

role in welcoming India and the UAE to the next phase of growth. To know more about how Moglix can augment and optimize the procurement process, click here

COP28 Climate Countdown: 1.5°C and Beyond

COP28 Climate Countdown: 1.5°C and Beyond

Amidst the global congregation at COP28, a singular figure commands attention—1.5°C. Beyond rhetoric, this term resonates in climate commitments and echoes on the Climate Clock. Unraveling the intricacies of “1.5°C” becomes imperative, exploring its genesis, repercussions, and the quest to achieve this milestone as the climate summit in Dubai looms.

Pinpointing the precise instance of breaching the 1.5°C threshold, as stipulated in the Paris climate accord, emerges as a nuanced quandary. The absence of a universally embraced definition for long-term global warming prompts diverse interpretations, fueling debates on the timeline for surpassing the 1.5°C goal.

While projections hint at an imminent short-term ascent to this temperature rise, potentially within the next few years, the complexities of climate trends, measured over decades, complicate pinpointing the exact breach of the Paris Agreement. Richard Betts of the UK Met Office’s Hadley Centre proposes an innovative strategy—intertwining global temperature observations from the past decade with forecasts for the next ten years. This proposition seeks to establish a universally accepted metric for global warming, potentially galvanizing immediate actions to avert further temperature escalations.

The Unexpected Ambition of 1.5C:

The 1.5C “stretch target” within the Paris Agreement emerged unexpectedly, defying initial expectations. Myles Allen, a professor at the University of Oxford, acknowledges the surprise, emphasizing the ambition of the agreement. Rooted in assessments of climate change impacts at varying warming levels, the 1.5C target gained prominence. Scientific evaluations revealed notable advantages, such as reduced extreme heat and the preservation of crucial polar sea ice, prompting a collective global focus on this ambitious goal.

Setting a Focal Point for Global Action:

Before the Paris Agreement, the world lacked a definitive target to rally around in combating climate change. The adoption of the 1.5C figure marked a pivotal moment in the climate change community. Pauline Dube, an environmental scientist, underscores its significance as a unified global goal, providing a shared direction for concerted efforts to mitigate the impacts of climate change.

For vulnerable regions, notably small islands and low-lying nations, grappling with intensifying storms, rising sea levels, and environmental degradation, the 1.5C scenario remains an existential challenge. Securing adequate loss and damage funding emerges as a pivotal component for the sustained survival and adaptation of these at-risk regions. Beyond current conditions, a 1.5C world confronts heightened risks of extreme heat, amplified stress on food production and water access, and an expanded spectrum of insect-borne diseases like malaria and dengue fever.

Regions like the Arctic, witnessing nearly four times faster warming since 1979, and Africa, experiencing a rapid 0.3C per decade increase between 1991 and 2020, surpassing the global average, exemplify the localized impacts. The timeline for surpassing the 1.5C mark presents intricate projections. The IPCC initially estimated a 50% chance of reaching 1.5C by the mid-2030s. However, recent analyses incorporating updated data suggest a potential earlier milestone, as soon as 2029. The discrepancy between passing 1.5C on individual days, months, and years versus the decadal average adds complexity to the assessment.

Navigating this nuanced landscape, Professor Myles Allen, a lead author on the IPCC report, emphasizes the impracticality of fixating on the precise year of crossing the 1.5C threshold. The intricacies of accurately estimating global temperature changes from decade to decade underscore the need for a holistic understanding rather than fixation on specific timelines. As we grapple with the unfolding climate dynamics, contextualizing these complexities becomes pivotal for informed discourse and strategic decision-making.

The fluidity of estimates regarding when we will breach the critical 1.5C warming mark underscores the intricate interplay of climate policies and evolving scientific analyses. As nations recalibrate their climate strategies, the projected timelines for reaching 1.5C are subject to adjustments. Similarly, refinements in climate models, often fueled by re-analyses of historical climate data, contribute to nuanced alterations in estimates.

A notable instance postdating the IPCC’s 1.5C report involves scientists revisiting the historical climate record. The outcome, revealing a 0.2C increase relative to preindustrial levels, amplifies the urgency of our proximity to the 1.5C threshold. Professor Myles Allen emphasizes that when confronted with such proximity, the inevitability of reaching 1.5C in approximately a decade becomes self-evident.

Delving into the gradations of warming, the distinction between 1.5C and 2C emerges starkly. While the impacts intensify with each degree of warming, the acceleration of impact severity per degree amplifies as temperatures rise. This underscores the pivotal role of incremental temperature changes, elucidated by Allen’s insight into the adaptation of ecosystems and economies to the climate of the late 19th and early 20th Century. As we navigate this intricate terrain, the imperative lies in grasping the cascading consequences of each temperature increment and their profound implications for the world as we know it.

As the specter of overshooting the 1.5C threshold looms, a poignant report unveiled at COP28 by climate and social scientists paints a stark picture of the inevitability of this trajectory. The emphasis lies not only on breaching the 1.5C threshold but also on mitigating the scale and duration of this overshoot, recognizing its profound implications for climate tipping points, vulnerable societies, and the delicate balance of ecosystems and economies.

The report underscores the critical need to comprehend not just whether we surpass 1.5C but the temporal dimensions of dwelling above this critical warming level. Prolonged overshoot intensifies the risk of crossing irreversible climate thresholds, amplifying damage to societies, ecosystems, and economies that bear the brunt of climate vulnerability.

Averting overshoot demands a substantial 43% reduction in emissions compared to 2019 levels, presenting a formidable challenge for global stakeholders. Sir David King, leading the Climate Crisis Advisory Group (CCAG), asserts that while overshoot is undesirable, prompt emission reduction remains the safest recourse. However, acknowledging overshoot as a potential backstop, King highlights the imperative of massive-scale carbon capture technologies, projected to absorb 10 to 15 billion tonnes of carbon dioxide annually. This staggering magnitude, surpassing EU and US emissions, underscores the monumental task ahead.

Crucially, reversing overshoot requires integrating these technologies alongside rigorous emission reduction, emphasizing the urgency of advancing carbon capture on an unprecedented scale. The financial and temporal costs of this endeavor, compounded by the centuries-long recovery period for crucial systems, underscore the imperative of prioritizing proactive measures to sidestep overshoot. As the world grapples with the complexities of climate intervention, the deliberation on avoiding overshoot versus navigating its consequences emerges as a pivotal dialogue in shaping our collective climate destiny.

Amid the labyrinth of climate negotiations at COP28, keen observers are on the lookout for promising indicators that could steer the trajectory toward staying within the 1.5C warming limit. As sustainability enthusiasts, we focus on key markers that reflect a collective commitment to decarbonization and climate justice.

Sir David King, a stalwart in climate diplomacy, places a spotlight on the crucial role of robust leadership from global heavyweights, the United States and China. Highlighting the recent collaborative agreement on climate action between the two nations, King emphasizes the pivotal nature of their strategic approach. A domino effect is anticipated, with the European Union, India, and Brazil potentially joining forces when presented with a compelling strategy.

For Professor Myles Allen, an advocate of positive tipping points, the transformative potential lies in accelerating decarbonization. He pinpoints encouraging shifts in renewable power dynamics and the surging adoption of electric vehicles as beacons signaling a positive tipping point.

Environmental scientist Pauline Dube underscores the urgency of a paradigm shift, acknowledging the profound injustice inherent in climate change, particularly impacting the Global South. Dube stresses the need for an inclusive, whole-society transformation, characterized by fairness, robust support for adaptation, and dedicated funding for climate-vulnerable nations grappling with loss and damage.

As we traverse the intricate landscape of COP28, these signs of progress inspire hope and illuminate the collective journey toward a sustainable, equitable future. The unfolding narrative at the intersection of global leadership, decarbonization milestones, and climate justice narratives forms a tapestry of promise in our pursuit of a 1.5C-resilient world.

Alarm Bells Ringing at COP28: Global Stocktake in focus

Alarm Bells Ringing at COP28: Global Stocktake in focus

As COP28 approaches, the first-ever global stocktake casts a stark light on our collective climate progress. While the Paris Agreement goals remain, the reality paints a sobering picture: we’re off track. The 1.5°C target hangs precariously, and the window for meaningful change is rapidly narrowing. This critical juncture demands immediate action.

COP28 presents a pivotal opportunity. The global stocktake serves as a mirror reflecting both our achievements and shortcomings, guiding us towards more ambitious climate action plans. Governments will make a crucial decision at COP28, one that can set the course for our collective future. This decision holds the potential to accelerate ambition, unlock resources, and propel us towards a sustainable tomorrow.

Yet, the path forward demands more than mere words. We must collectively rise to the challenge, leveraging the global stocktake as a springboard for urgent action. Join us as we delve deeper into the implications of the global stocktake, exploring the challenges that lie ahead and the opportunities we must seize. Together, let us amplify the call for action and build a world where climate ambition translates into tangible results.

What is Global Stocktake?

Imagine taking a comprehensive inventory of your home, examining each item and its purpose. This is precisely what the global stocktake does for climate action. It’s a meticulous process of assessing our collective progress, identifying areas where we’re falling short, and collaboratively charting a course for a more sustainable future.

Occurring every five years, the global stocktake will culminate at COP28, offering a critical opportunity to inform the next round of climate action plans known as NDCs. By holding up a mirror to our collective efforts and highlighting areas needing improvement, the stocktake empowers policymakers and stakeholders to strengthen their commitments and pave the way for accelerated action.

Think of it as a strategic pause to assess our journey towards the Paris Agreement goals. It’s a chance to identify gaps, learn from successes and failures, and ultimately, chart a more ambitious course forward. By embracing the insights gained from this global inventory, we can collectively translate good intentions into concrete action, propelling us towards a more sustainable and resilient future.

The Scope of the Global Stocktake

The global stocktake goes beyond a mere assessment of progress. It delves into the very core of our collective climate action, scrutinizing three key areas:

- Mitigation: This pillar focuses on evaluating how successfully we’re reducing greenhouse gas emissions. It analyzes our progress towards the ambitious targets of keeping global warming below 2°C and ideally 1.5°C, while identifying potential for even deeper emission cuts.

- Adaptation: Here, the stocktake assesses how countries are strengthening their resilience and reducing vulnerabilities to climate impacts. It examines their ability to adapt to the changing climate and minimize potential damage.

- Means of Implementation: This area scrutinizes the financial, technological, and capacity-building support provided to developing nations. It evaluates the alignment of financial flows with emissions reduction and climate-resilient development goals, ensuring that these nations receive the resources they need to tackle the climate crisis effectively.

Furthermore, the global stocktake extends its reach to address:

- Loss and Damage: This examines the actions and support needed to respond to climate impacts exceeding a community or ecosystem’s ability to adapt. It recognizes the devastating consequences of climate change and seeks solutions to address them.

- Response Measures: This acknowledges the potential unintended social and economic consequences of climate action. It seeks to minimize these impacts and ensure that climate action is implemented in a just and equitable manner.

- Science and Equity: The stocktake emphasizes the importance of relying on the best available science to inform climate strategies. It also underscores the critical need for promoting equity and ensuring that all stakeholders are involved and benefit from the transition to a sustainable future.

In essence, the global stocktake acts as a comprehensive audit of our climate action efforts, leaving no stone unturned in its quest for a more sustainable tomorrow. By rigorously examining every aspect of our progress, we can identify areas for improvement, strengthen our commitments, and pave the way for a future where climate action is the norm, not the exception.

A Stark Wake-Up Call

While the Paris Agreement has undoubtedly spurred global climate action, the sobering reality revealed by the global stocktake is that implementation falls short across all areas. The ambitious 1.5°C target remains elusive, and current emissions trends paint a bleak picture. Despite pockets of progress, adaptation efforts are insufficient to meet the growing challenges of climate change.

The stocktake emphasizes the need for a radical shift – a systems transformation. This entails a whole-society, whole-economy approach that seamlessly integrates climate resilience and development with low greenhouse gas emission strategies. Such sustained efforts over decades are crucial to achieving sustainable development and eradicating poverty, ensuring a future where both environmental and human needs are met.

However, a stark disparity exists between the needs of developing nations and the support provided. The stocktake calls for unlocking and redirecting trillions of dollars towards climate action and climate-resilient development in these countries. Only by closing this financial gap can we ensure a just and equitable transition to a sustainable future for all.

The global stocktake is not merely an assessment; it’s a clarion call for action. It serves as a roadmap for closing the implementation gap, reminding us of the urgency and the magnitude of the task ahead. By embracing the insights it offers, we can collectively chart a more ambitious course, transforming our climate action efforts into tangible results that safeguard the planet for generations to come.

Findings hint towards a Call for Urgent Action

The initial findings of the Global Stocktake paint a clear picture: we are not doing enough. Despite some progress, the current trajectory of climate action falls short on all fronts, jeopardizing the long-term goals of the Paris Agreement.

Key findings across the three main goals are alarming:

Mitigation:

- Emissions Gap: Current national plans leave a massive gap of 20-24 billion tons of CO2 equivalent between projected emissions and what’s needed for a 1.5°C pathway.

- Ambition Needed: Updated NDCs must be significantly more ambitious, including phasing out fossil fuels and halting deforestation.

- Cost-Effective Solutions: Green industrialization and other strategies offer opportunities to cut emissions while promoting development.

- Just Transition: Shifting away from fossil fuels requires careful planning to minimize disruptions to jobs and communities.

Adaptation:

- Closing Window: The window to adapt to climate impacts is rapidly closing, demanding urgent action.

- Fragmented Efforts: While ambition is increasing, adaptation actions are often disconnected, incremental, and unequally distributed.

- Local Context Matters: Adaptations must be driven by local needs and populations, including marginalized groups.

- Scaling Up Finance: Rapidly increasing finance for adaptation and addressing loss and damage is crucial.

Implementation and Finance:

- Finance Shortfalls: Despite progress, developed countries are not providing enough financial support to developing countries.

- Global Financial Transformation: The global financial system needs to be redesigned to support climate action.

- Simplified Access: Developing countries need easier access to international climate funds.

- Technology Transfer: Accelerating technology transfer is vital for implementing climate solutions.

Implications for the Future:

The Global Stocktake findings demand a strong political response from countries. This includes:

- Updated NDCs: Countries must significantly increase the ambition of their national climate action plans by 2025.

- Biennial Transparency Reports: These reports will track progress towards agreed goals.

- Ratcheting Up Mechanism: The Global Stocktake is a key element in the process of continuously strengthening climate action to meet the Paris Agreement goals.

The Global Stocktake serves as a wake-up call. It is time to move beyond incremental change and embrace a transformative approach to climate action. We must act collectively and urgently to secure a sustainable future for all.Next Steps after the Global Stocktake

UAE is making Abayas go Sustainable

UAE is making Abayas go Sustainable

In a land known for its opulence and architectural marvels, a new wave of Eco-consciousness is sweeping across the United Arab Emirates (UAE). The UAE, with its towering skyscrapers and luxurious lifestyle, is embracing a more sustainable and environmentally responsible future. This transformation is evident in the innovative initiatives that are turning plastic bottles into stylish clothing and crafting biodegradable Abayas, a traditional attire worn by many Emirati women.

A Sustainable Vision for the Future

Deeply embedded in the UAE’s long-term vision is a strong commitment to being eco-friendly, especially when it comes to managing waste. The goal is pretty ambitious: cut down on carbon emissions, protect nature, and encourage practices that use sustainable energy. And guess what? The fashion industry is taking the lead in making this happen, making it a crucial part of the UAE’s promise to take care of the climate.

Now, when we talk about sustainable fashion in the UAE, here’s something really cool – they’re turning used plastic bottles into clothes. It isn’t just about helping the environment; it’s also a bold fashion move. Big brands are jumping on board, making the UAE a trendsetter in turning piles of plastic waste into stylish clothing.

But that’s not all. The UAE’s sustainable fashion scene also loves materials that can easily go back to nature, like bamboo, organic cotton, and Tencel. These are the good-for-the-environment fabrics used to make traditional Abayas. So, not only are these clothes comfy and breathable, but they’re also a way of saying, “Hey, we care about the planet.”. In the UAE, they’re not just making clothes; they’re telling a story of style that goes hand in hand with taking care of our world.

Sustainable Local Excellence

DGrade: This Dubai-based company specializes in transforming millions of discarded plastic bottles into high-quality yarn. The process involves collecting, sorting, washing, and shredding plastic bottles into small flakes. These flakes are then melted and spun into threads, which are woven into soft, breathable, and sturdy fabrics. DGrade’s recycled polyester is used to create a range of clothing, including Abayas, T-shirts, jackets, and hats.

Al Amira Fashion: Another Dubai-based brand, Al Amira Fashion, specializes in sustainable Abayas crafted from bamboo, organic cotton, and Tencel. These Abayas offer breathability, moisture-wicking properties, and a silky touch. They are wrinkle-resistant and easy to maintain. The organic cotton used in their production is farmed without the use of pesticides or herbicides, while Tencel Abayas are created from sustainable wood pulp.

Fashion made from recycled plastic bottles and biodegradable materials brings several environmental benefits. First and foremost, it significantly reduces plastic waste, thereby conserving natural resources. Additionally, it plays a role in reducing greenhouse gas emissions. DGrade, for instance, has contributed to recycling an impressive 60 million plastic bottles since its inception, leading to a substantial reduction in global plastic waste.

Sustainable Abayas from Al Amira Fashion also contribute to environmental preservation. Bamboo Abayas save water and reduce the need for pesticides. Organic cotton Abayas help conserve water and eliminate the use of pesticides, while Tencel Abayas play a role in minimizing deforestation.

COP28: A Global Stage for Environmental Action

In November 2023, Dubai, UAE, will host the 28th Conference of the Parties (COP28) to the United Nations Framework Convention on Climate Change (UNFCCC). COP28 is a crucial global event where world leaders converge to address climate change and formulate strategies to reduce greenhouse gas emissions.

Sustainable fashion stands as a prime example of the UAE’s environmental efforts, aligning with the Dubai Fashion & Design Council’s Sustainability Program and other government initiatives. These efforts not only support sustainability in fashion but also contribute to a larger global movement towards a greener and more responsible fashion industry.

Inspiring an Eco-Conscious future with Style

The journey towards sustainable fashion in the UAE has only just begun. The future holds promise, with potential collaborations with international brands, ongoing research into eco-friendly materials, and educational efforts aimed at raising awareness about responsible fashion practices. With the world’s eyes on the UAE, this nation is poised to inspire a global shift towards Eco-conscious and sustainable fashion.

In a region renowned for luxury and extravagance, the UAE is boldly embracing a more sustainable path, symbolized by the transformation of discarded plastic bottles into garments and the creation of biodegradable Abayas. As the world gears up for COP28, the UAE positions itself as a champion of sustainable living and climate responsibility.

Moglix, an Asia-based B2B commerce startup, is playing a pivotal role in the UAE’s sustainable economic landscape. The company is aligned with the UAE’s vision for a greener future by assisting SMEs and major organizations in digitizing their procurement processes. Learn more about how Moglix is at the forefront of promoting sustainability in procurement, aligning perfectly with the UAE’s journey towards a more sustainable future.

The Solar Renaissance in the UAE: Illuminating Tomorrow

The Solar Renaissance in the UAE: Illuminating Tomorrow

In the arid expanse of the Arabian desert, where temperatures soar and sunlight prevails, the UAE, synonymous with towering skyscrapers and a flourishing oil economy, is pioneering a transformative solar revolution to embrace a greener future. Let’s delve into the radiant world of the UAE, embracing solar energy as a beacon for sustainable progress.

The Current Solar Endeavors in the UAE

The UAE’s expanding solar portfolio underscores its steadfast commitment to solar power. Notably, Dubai’s Mohammed bin Rashid Al Maktoum Solar Park, positioned as the world’s largest single-site solar park, is set to generate 5,000 megawatts by 2030 across 40 sq. km.

Smaller yet significant projects, including the 1,177-megawatt Noor Abu Dhabi Solar Plant, mirror the nation’s dedication to energy diversification and reducing reliance on fossil fuels. As of September 2021, solar power constitutes 9% of the UAE’s total energy consumption, a figure expected to ascend with the nation’s unwavering commitment to solar energy.

Motivation Behind the UAE’s Solar Transition

The UAE’s pursuit of solar energy extends beyond economic diversification. Driven by environmental consciousness, the nation aims to mitigate the ecological repercussions of fossil fuel dependency. By embracing solar electricity, the UAE not only secures its energy future but also positions itself as a global environmental advocate actively combating climate change.

The UAE’s solar initiative yields unique advantages beyond clean energy generation. It stabilizes the energy supply, mitigating the country’s vulnerability to oil price fluctuations. Moreover, the shift towards green energy fosters economic growth and technological innovation, establishing the UAE as a pioneering force in renewable energy. This, in turn, attracts investments and enhances the nation’s global image.

Government-Led Initiatives Fueling the Solar Momentum

The UAE government spearheads the solar revolution, offering incentives like feed-in tariffs and power purchase agreements to entice private-sector participation in renewable energy projects. Noteworthy is the UAE Council for Climate Change and Environment, showcasing the nation’s commitment to sustainability.

The UAE’s solar future shines brightly, with explorations into concentrated solar power and energy storage technologies to enhance efficiency and reliability. Collaborations with international partners and experts will likely play a pivotal role in realizing these sustainable development goals.

The robust environmental connection between India and the UAE sees Indian enterprises actively engaging in solar projects. This collaboration, driven by shared concerns about energy needs, serves as a model for sustainable development.

COP28: A Pinnacle in the UAE’s Climate Endeavors

As the UAE strides towards Net Zero emissions, its hosting of COP28 in Dubai from November 30 to December 12, 2023, aligns seamlessly with its solar power commitment. The global platform will showcase the UAE’s achievements in SDGs and advocate for collective action on climate change.

The UAE’s solar revolution marks a monumental stride towards a sustainable and eco-friendly future. Beyond the realm of solar technology, industries such as B2B trade are embracing solar power to foster growth. Pioneering this transition is Moglix, a key player in providing supply chain and digital procurement solutions. Explore the transformative impact of technology on efficiency, cost reduction, and global industry growth with Moglix.

Dubai’s Pioneering Journey Towards 100% Water Utilization

Dubai’s Pioneering Journey Towards 100% Water Utilization

Dubai, the vibrant metropolis of the UAE, is renowned for its opulence and innovation. In recent years, the city has embarked on a remarkable journey toward achieving 100% water consumption, aligning with its role as the host of COP28, its commitment to sustainable practices, SDG goals, and global leadership.

The Uniqueness of Dubai’s Water Challenge

Dubai’s water management challenges are as unique as the city itself. Nestled in a desert climate characterized by scorching heat and limited freshwater sources, Dubai has had to employ innovative water sustainability strategies. The city’s rapid urbanization and population growth have put significant stress on these water resources, making water efficiency a paramount concern. The exacerbation of these problems due to rising global temperatures, a consequence of climate change, adds to the complexity.

The Dubai Way: Recycling and Desalination

Dubai’s ambitious goal of achieving 100% water utilization hinges on two primary methods: recycling and desalination.

Wastewater Recycling: Dubai Municipality has introduced cutting-edge wastewater treatment plants that adhere to rigorous quality standards. This purified water, known as “gray water,” finds application in irrigation, cooling, and industrial processes. This strategy not only conserves precious freshwater but also reduces the environmental impact associated with wastewater discharge.

Desalination: Recognizing the pressing need for freshwater in this arid region, Dubai has made substantial investments in desalination technology. The city boasts some of the world’s largest desalination plants, which efficiently convert saltwater into freshwater. The Dubai Way optimizes desalination processes to minimize energy consumption and environmental consequences.

The Evolution of Water Reclamation

Dubai’s journey towards water reclamation began in the late 1960s, marking a pivotal turning point in the city’s sustainable growth. In 1969, the Dubai Municipality established the first wastewater treatment plant in Al Khawaneej. The rapid urbanization of Dubai necessitated an expanded wastewater treatment and reclaimed water capacity, leading to the inauguration of the Warsan plant in 1981. By 2006, Jebel Ali further expanded Dubai’s water recycling capacity to meet the burgeoning demand for reclaimed water, bolstering water conservation efforts.

The Future of Dubai’s Water Management

Dubai’s water management objectives closely align with the goals of COP28 and the UN’s Sustainable Development Goals (SDGs). As the host of COP28, Dubai seeks to serve as a global exemplar of sustainable practices. The city is determined to make its water consumption sustainable and reduce its overall water footprint. This is being achieved through:

Innovation: Dubai is actively funding research in water purification and desalination energy efficiency. The city leverages modern technology and intelligent systems for the monitoring and regulation of water usage.

Public Awareness: Dubai Municipality vigorously promotes water conservation among its residents and businesses. Awareness campaigns and incentives play a crucial role in encouraging people and enterprises to adopt water-saving practices.

Sustainable Cities: Dubai is pioneering sustainable urban development in the region. Projects like Masdar City and Sustainable City Dubai exemplify water-sustainable, energy-efficient, and environmentally friendly urban living.

Dubai’s ambitious quest for 100% water utilization sets a remarkable example of sustainability and innovation. The city has harnessed the power of recycling and desalination to secure its water future, overcoming distinctive challenges. By hosting COP28 and adhering to the principles of the SDGs, Dubai showcases its unwavering commitment to the global community. The city’s ultimate aspiration is to eradicate water scarcity and construct sustainable desert communities by embracing the Dubai Way.

Moglix in the UAE is working in this space to ensure organisations (private and public)their sustainability goals are aligned with their procurement goals. Moglix is the most comprehensive procurement solution in the UAE, that combines E catalog based buying experience, digital procurement and supply chain solution with a physical warehouse and logistics network, allowing you a complete and most comprehensive E2E procurement and supply chain solution. Reach Us

COP 28: The Middle East’s Adaptive Reuse Phenomenon is Revolutionizing Sustainability

COP 28: The Middle East’s Adaptive Reuse Phenomenon is Revolutionizing Sustainability

The grandeur of the Middle East often overshadows the pressing need for sustainable practices in the region. As the world marches towards a greener future, the Middle East is now awakening to the potential of adaptive reuse, a trend that has been transforming underused buildings and sites worldwide. This concept is redefining the landscape of the Middle East and heralds a sustainable revolution in architecture and urban planning.

Adaptive Reuse: A Global Trend

Adaptive reuse, the process of reimagining older structures, is gaining momentum globally. It involves transforming underused buildings into more practical and functional spaces, ensuring that the architectural heritage is preserved while addressing modern urban needs. Cities like New York and London have been at the forefront of this trend, redefining their landscapes and preserving history simultaneously. New York’s One Wall Street, once an office building, has now found new life as a residential haven, and London’s No.1 Grosvenor Square is now a super-prime residential complex. Battersea Power Station, a decommissioned landmark, is currently undergoing transformation into a mixed-use development. These global success stories have set the stage for adaptive reuse to become a game-changing phenomenon.

Middle East is Adapting

In the Middle East, adaptive reuse is not a new concept. The UAE government has showcased the benefits of re-purposing old structures, with projects like the Bastakiya neighborhood and Al Serkal Avenue. The Bastakiya neighborhood now boasts cafes, art galleries, and boutique hotels, preserving its historical significance while fostering culture and community. Al Serkal Avenue, once an industrial zone, has become a hub for arts and culture, contributing to a vibrant arts community.

Expo City Dubai exemplifies the potential of adaptive reuse. The site, originally developed for World Expo 2020, has been entirely reimagined into a self-sustaining, 15-minute city. It prioritizes eco-friendliness, with green roofs and smart energy-saving appliances, setting a new standard for sustainable living. This transformation not only pays homage to the area’s past but also presents a promising future for the region

The Middle East is embracing sustainability as a core value. Re-purposing existing structures instead of constructing new ones significantly reduces carbon emissions, aligning with the United Nations Environment Program’s call to address the construction sector’s high carbon footprint. With the UAE’s construction market soaring, the need for sustainable solutions is evident.

‘Year of Sustainability

The UAE declared this year the ‘Year of Sustainability,’ aligning with COP28, emphasizing the importance of sustainable living. This move is expected to encourage regional developers to prioritize sustainability in their projects. As more people choose the Middle East as their home, the demand for housing and entertainment destinations will rise. Adaptive reuse projects offer an efficient and sustainable option to meet these needs. Buyers are increasingly drawn to high-quality adaptive reuse projects, and this trend is likely to continue. It’s an exciting era for sustainable development in the region.

Moglix in the UAE is working with real estate and construction companies to ensure their sustainability goals are aligned with their procurement goals. Moglix is the most comprehensive procurement solution in the UAE, that combines E catalog based buying experience, digital procurement and supply chain solution with a physical warehouse and logistics network, allowing you a complete and most comprehensive E2E procurement and supply chain solution. Reach Us

UAE and India: Crafting a High-Tech Future Together

UAE and India: Crafting a High-Tech Future Together

In a remarkable stride towards strengthening their economic and technological bonds, the United Arab Emirates (UAE) and India have unveiled a vision to bolster sustainable industrial development. This dynamic partnership sets the stage for mutual investments, technology transfers, and the adoption of cutting-edge innovations across various industries. The memorandum of understanding (MoU) was signed during the 11th meeting of the UAE-India High-Level Joint Task Force on Investments, showcasing a remarkable leap forward in their collaborative journey.

So, what’s in the pipeline? Let’s dive into this exciting alliance, where two nations join hands in a harmonious rhythm of growth and development.

Economic Partnership for the Ages

The MoU aligns seamlessly with the UAE-India Comprehensive Economic Partnership Agreement (CEPA). This strategic pact is a game-changer, designed to elevate trade and logistics ties between these two vibrant nations. The recent signing ceremony, presided over by Dr. Sultan Al Jaber, UAE Minister of Industry and Advanced Technology, and Piyush Goyal, India’s Minister of Commerce and Industry, marked a milestone in the strengthening of bilateral relations.

The Magnificent Seven: Key Areas of Collaboration

The collaborative efforts under the MoU are set to shape the future in seven key areas. Let’s take a sneak peek into what’s on the horizon:

1. Supply Chain Synergy

The UAE and India will join hands to identify opportunities for the supply of raw materials.

They’ll be sharing best practices for industrial growth, making sure this cooperation thrives in various domains, from energy to land, and technology to labor incentives.

2. Energizing the Future

Energy storage technologies, Smart Grid deployment, and IoT applications will be the focus.

Extensive research and development (R&D) in renewable energy and energy efficiency will lead to sustainable advancements.

3. Health & Life Sciences

Collaborating in the development of pharmaceuticals and unleashing the power of biotechnology.

Expect groundbreaking R&D to create innovations that’ll redefine healthcare.

4. Beyond the Stars

A combined mission to elevate their space industries, including the development, launch, and utilization of small satellites.

They’re even exploring space exploration and licensing of space-related materials – sounds like a journey to the cosmos!

5. AI-Powered Progress

With AI at the helm, the UAE and India are set to elevate multiple sectors, from space and energy to healthcare and supply chains.Advanced machine learning and data analytics are also on the roadmap for these forward-thinking nations.

6. The Revolution of Industry 4.0

Get ready for real-time data processing, autonomous robotics, and additive manufacturing across industries.These are the building blocks of the Fourth Industrial Revolution (4IR), shaping the industries of tomorrow.

7. Standardization and Beyond

Here, the focus is on standardization, metrology, conformity assessment, accreditation, and Halal certification.Their aim? To harmonize standards with international requirements and foster mutual recognition of conformity assessment results.

A Vision of Sustainable Growth

Dr. Sultan Al Jaber emphasizes that this MoU perfectly aligns with the UAE’s national industrial strategy and the “Make it in the Emirates” initiative. This ambitious venture seeks to transform the UAE into a global hub for advanced industries, especially those destined for the future.

Piyush Goyal, India’s Minister of Commerce and Industry, highlights the potential of the MoU to unlock new dimensions in emerging technologies. From space exploration to healthcare, renewable energy, artificial intelligence, and more, this collaboration is poised to break new ground.

As per the MoU, the UAE and India will join forces in industrial and academic collaborations, collaborative research and development projects, and best practice sharing. This partnership is more than just an agreement; it’s a catalyst for economic growth, diversification, and sustainability across key industries.

In this era of limitless possibilities, the UAE and India are crafting a high-tech future together. It’s not just an alliance; it’s a glimpse into the limitless potential of shared dreams and endeavors.As these nations bridge the divide, the rest of the world watches with bated breath, eager to see the remarkable transformation they’ll bring to life. After all, the future has never looked more promising.

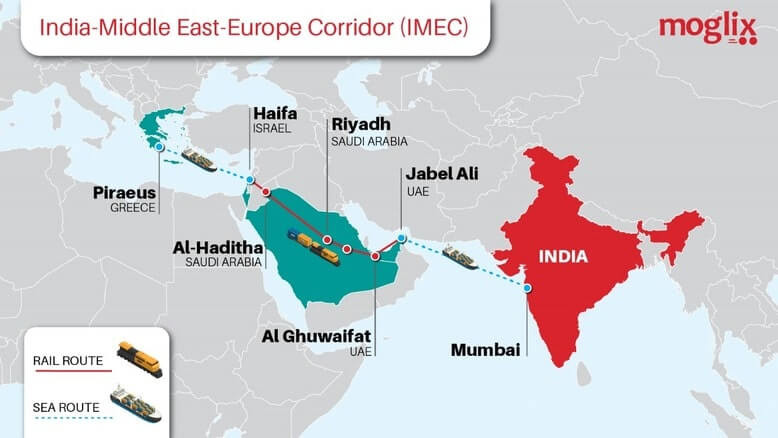

The India-Middle East-Europe Economic Corridor – All you should know about

The India-Middle East-Europe Economic Corridor – All you should know about

In a significant development during the recently concluded G20 summit held in New Delhi, India, a groundbreaking initiative was unveiled, with far-reaching implications for geopolitics and global connectivity. The United States, India, Saudi Arabia, the United Arab Emirates, along with France, Germany, Italy, and the European Union, jointly introduced the India-Middle East-Europe Corridor (IMEC). This ambitious project aims to foster economic development by enhancing connectivity and integration between Asia, the Arabian Gulf, and Europe. While it carries profound implications for global trade and politics, the IMEC also represents a dynamic shift in regional alliances and aspirations.

The IMEC at a Glance

The India-Middle East-Europe Corridor is a multimode transit corridor spanning over 3,000 miles, consisting of two primary corridors. The eastern corridor connects India to the Arabian Gulf, while the northern corridor links the Arabian Gulf to Europe. This extensive project, as outlined in the White House’s memorandum of understanding, will establish a reliable and cost-effective cross-border ship-to-rail transit network. It is designed to complement existing maritime and road transport routes, facilitating the seamless movement of goods and services between India, the UAE, Saudi Arabia, Jordan, Israel, and Europe. It is not limited to rail and shipping routes; rather, it includes an electricity cable, a hydrogen pipeline, and a high-speed data cable. This diverse range of infrastructure projects is poised to enhance trade and energy flows among the participating countries.

A Counter to China’s Belt and Road Initiative

China’s Belt and Road Initiative (BRI) has been a prominent player in global infrastructure development over the past decade. However, recent data suggests a stagnation in the value of new foreign contracted projects under the BRI since its peak in 2019, coinciding with China’s domestic real estate debt crisis. This economic challenge has raised questions about the sustainability of China’s expansive infrastructure program.

One of the most noteworthy aspects of the IMEC’s unveiling was the swift positioning of the corridor as an alternative to China’s Belt and Road Initiative (BRI). The BRI has significantly expanded China’s influence by developing trade and infrastructure networks across Asia, Europe, and Africa. However, the IMEC is not simply a rival to the BRI; it represents a different approach to regional cooperation.

Saudi Arabia and the UAE, central players in the IMEC, have shown reluctance to engage in a bipolar world order that forces them to choose between China and the United States. Their active participation in both the IMEC and their recent admission to the BRICS group of major emerging economies underscores their commitment to maintaining autonomy and safeguarding their sovereignty.

Deepening Integration and Economic Convergence

The IMEC underscores the deepening integration between India, Saudi Arabia, and the UAE, signifying broader geopolitical and economic convergence between the Middle East and South Asia into West Asia. India has become Saudi Arabia’s second-largest trading partner, with bilateral trade reaching $52.75 billion during 2022-23, elevating Saudi Arabia to India’s fourth-largest trading partner. Similarly, trade between India and the UAE surged to $85 billion in 2022, positioning the UAE as India’s third-largest trading partner for the year 2022-23 and its second-largest export destination.

This shift in regional dynamics also reflects the evolving state of Pakistan-Gulf relations, where Saudi Arabia and the UAE have adjusted their economic and geopolitical posture toward India. This shift acknowledges India’s rising influence and signifies the aspirations of Gulf nations in the emerging multipolar world. In this changing landscape, traditional alliances are being reevaluated to align with geopolitical realities and economic opportunities.

Beyond Energy: Diversification and Autonomy

The IMEC signifies that Gulf states, particularly Saudi Arabia and the UAE, are actively seeking diverse economic and technological partnerships beyond their role as energy producers. While energy remains a core pillar of their economies, the IMEC highlights that they are determined to establish more diversified and resilient economies.

For years, Washington has primarily approached Gulf states with an energy-centric perspective. However, the IMEC signals a shift towards recognizing that bilateral relations with Saudi Arabia and the UAE are multidimensional. Energy is a significant component, but it is not the sole focus. The United States aims to change the trajectory in the Gulf by involving India in both geopolitical and economic aspects.

Way forward

The India-Middle East-Europe Economic Corridor is not merely an infrastructure project; it is a geopolitical game-changer. It signifies the evolving landscape of alliances, the quest for autonomy, and the recognition that the Gulf states are integral players in the global economy. As the project unfolds, it has the potential to reshape the future of connectivity, trade, and geopolitical influence in the Middle East, Asia, and Europe. The IMEC is a declaration that global partnerships can transcend traditional boundaries and create a more interconnected and prosperous world.