Procurement Outsourcing: How CPOs & Businesses Can Cut Costs & Boost Efficiency

Procurement Outsourcing: How CPOs & Businesses Can Cut Costs & Boost Efficiency

In today’s rapidly evolving business landscape, companies constantly seek ways to reduce costs and boost efficiency.

One smart way to do this is through procurement outsourcing. For Chief Procurement Officers (CPOs) and businesses, outsourcing procurement tasks reduces hassle and frees up time to focus on core activities.

By handing over purchasing and supplier management to experts, companies can save money, reduce workload, and improve their overall operations.

In this blog, we will explore the benefits of procurement outsourcing, how it enhances efficiency, and the key strategies businesses can adopt to make the most of it.

Understanding Procurement Outsourcing

Procurement outsourcing involves delegating tasks like sourcing, purchasing, vendor management, and contract negotiations to a third-party provider.

It allows businesses to optimize their supply chain, reduce operational burdens, and achieve procurement cost savings without compromising on quality or compliance.

According to the 2025 State of Procurement Data Report by Amazon Business, procurement is evolving from merely a cost-cutting function to a strategic driver of growth and innovation.

This shift emphasizes the importance of supplier relationships and digital transformation in enhancing procurement effectiveness.

As procurement becomes more than just a cost-saving tool, businesses that leverage procurement outsourcing can stay ahead by focusing on strategic sourcing, supplier collaboration, and technology integration.

Benefits of Procurement Outsourcing for Businesses

Outsourcing procurement functions offers numerous advantages to organizations, regardless of size. Here’s how businesses can benefit:

1. Procurement Outsourcing Drives Procurement Cost Savings

One of the biggest reasons businesses opt for procurement outsourcing is to achieve significant procurement cost savings.

Third-party providers leverage their industry expertise, bulk purchasing power, and extensive supplier networks to secure better pricing and lower overhead costs.

Some ways procurement outsourcing reduces costs include:

- Optimizing supplier negotiations to secure better pricing

- Reducing administrative and operational expenses

- Streamlining the procurement process to avoid unnecessary purchases

- Minimizing risks related to vendor management

2. Procurement Outsourcing Enhances Indirect Procurement Solutions

Indirect procurement solutions involve purchasing goods and services that are not directly linked to manufacturing but are essential for daily business operations.

This includes office supplies, IT equipment, and facility maintenance services.

By outsourcing indirect procurement solutions, businesses can:

- Reduce maverick spending and ensure compliance with company policies

- Improve supplier consolidation and negotiation

- Gain better visibility into procurement spending

3. Strategic Sourcing Through Procurement Outsourcing

A well-planned procurement strategy relies heavily on strategic sourcing—analyzing and selecting suppliers for long-term value, not just cost.

Procurement outsourcing partners specialize in strategic sourcing by:

- Conducting market research to find cost-effective suppliers

- Implementing data-driven decision-making in supplier selection

- Enhancing contract negotiations to ensure long-term value

4. Vendor Management Becomes More Efficient with Procurement Outsourcing

Effective vendor management is essential for maintaining strong supplier relationships, ensuring timely deliveries, and mitigating risks.

Outsourcing vendors take on the responsibility of:

- Evaluating and managing suppliers

- Handling contract negotiations and compliance

- Monitoring vendor performance

- Resolving disputes or issues with suppliers

With procurement outsourcing, businesses no longer have to invest heavily in in-house vendor management teams.

5. Procurement Outsourcing Supports Business Process Outsourcing Strategies

Many organizations are increasingly adopting business process outsourcing (BPO) strategies to enhance efficiency.

Procurement is a vital part of BPO, allowing companies to streamline operations and focus on their core competencies.

By outsourcing procurement functions, businesses can:

- Improve agility and scalability

- Optimize resource allocation

- Enhance compliance and risk management

6. Technology and Digital Transformation in Procurement Outsourcing

Modern procurement outsourcing relies on technology-driven solutions to boost efficiency.

With the rise of automation, artificial intelligence, and cloud-based procurement platforms, businesses can gain real-time insights and optimize their procurement processes.

Some key technologies enhancing procurement outsourcing include:

- E-procurement platforms for digitized purchase management

- AI-driven analytics for smarter supplier selection

- Blockchain technology for secure and transparent transactions

- Robotic Process Automation (RPA) to streamline procurement workflows

By leveraging technology, businesses can make informed purchasing decisions and ensure seamless procurement operations.

Implementing a Successful Procurement Outsourcing Strategy

For businesses and CPOs considering procurement outsourcing, it’s essential to develop a well-structured procurement strategy. Here’s how to ensure a smooth transition:

1. Define Clear Objectives

Before outsourcing procurement, businesses must identify their goals, whether it’s procurement cost savings, efficiency improvement, or vendor consolidation.

2. Choose the Right Procurement Partner

Selecting a reliable procurement outsourcing provider is crucial. Businesses should assess providers based on:

- Industry expertise

- Track record and client reviews

- Technological capabilities

- Flexibility and scalability

3. Integrate Technology for Seamless Procurement Outsourcing

Digital transformation plays a key role in procurement outsourcing.

Businesses should leverage e-procurement platforms, automation tools, and data analytics to gain real-time insights into procurement activities.

4. Monitor Performance and Optimize Procurement Outsourcing Efforts

Regular performance evaluations help ensure that the procurement outsourcing strategy delivers the desired results.

Key performance indicators (KPIs) such as cost reductions, supplier performance, and procurement cycle time should be monitored.

Optimize Your Procurement Operations with Moglix

Procurement outsourcing is an effective solution for businesses looking to cut costs and boost efficiency.

From indirect procurement solutions to strategic sourcing and vendor management, outsourcing procurement activities can significantly enhance a company’s procurement strategy.

For CPOs and business leaders, embracing procurement outsourcing is not just about reducing costs, it’s about unlocking long-term value, improving supplier relationships, and gaining a competitive edge in the market.

If you’re looking for a trusted partner to streamline your procurement processes, consider Moglix’s cutting-edge solutions tailored to your needs.

With a vast supplier network, technology-driven procurement platforms, and a proven track record in procurement outsourcing, Moglix can help you achieve procurement cost savings and operational excellence.

Get in touch with Moglix today to transform your procurement strategy and drive efficiency like never before!

Overcoming Indirect Procurement Challenges: Insights and Solutions for CPOs

Overcoming Indirect Procurement Challenges: Insights and Solutions for CPOs

Indirect procurement—covering essential non-production goods and services—poses distinct challenges for Chief Procurement Officers (CPOs).

While often overlooked in favor of direct procurement, indirect spending can represent a significant portion of a company’s overall expenditures.

Managing indirect procurement effectively is key to cost optimization, operational efficiency, and strategic business growth.

This article explores the key challenges CPOs face in indirect procurement and offers practical solutions for overcoming these hurdles.

Key Challenges in Indirect Procurement & How to Solve Them

Challenges:

- Lack of Visibility and Control: A lack of visibility into indirect procurement spend often leads to inefficiencies and cost overruns.

Decentralized purchasing, a lack of standardized processes, and disparate systems can make it difficult to gain a comprehensive view of where money is being spent.

This lack of visibility can lead to overspending, duplicated efforts, and missed opportunities for cost savings.

- Decentralized Procurement: Decentralized procurement leads to inefficiencies, inconsistent processes, and weaker supplier negotiation leverage.

Without a centralized approach, organizations miss out on the benefits of bulk purchasing, standardized contracts, and streamlined processes.

- Supplier Relationship Management: Managing a large and often fragmented supplier base can be a significant challenge.

Managing supplier compliance, performance consistency, and service levels across a fragmented base is resource intensive.

Without a strategic approach to supplier management, organizations may struggle to build strong, collaborative relationships that drive value.

- Maverick Spending: Maverick spending, where employees bypass formal procurement processes and make purchases independently, is a common issue in indirect procurement.

This can lead to higher costs, compliance violations, and a lack of control over spending.

Uncontrolled spending occurs when procurement policies are unclear, or the formal process is perceived as slow and inefficient.

- Cost Control and Budget Management: Rising costs and budget constraints challenge CPOs in optimizing indirect procurement.

Without accurate spending data and robust cost control measures, organizations can easily exceed budgets and miss opportunities for savings.

Solutions:

- Centralized Procurement Systems: A centralized procurement system enhances visibility, optimizes supplier management, and controls indirect spend.

Centralization enables the creation of standardized processes, leveraging bulk purchasing power, negotiating better contract terms, and improving spend visibility.

- Enhanced Supplier Management: Building strong, long-term relationships with key suppliers is essential for optimizing indirect procurement.

Strategic supplier management—focusing on collaboration, performance tracking, and risk reduction—improves procurement outcomes.

This includes consolidating the supplier base where possible, negotiating favorable contracts, and establishing clear performance expectations.

- Data Analytics: Advanced analytics tools help CPOs track spending trends, predict procurement needs, and uncover savings opportunities.

Spend analytics can help organizations identify areas of leakage, optimize pricing, and make data-driven decisions about supplier selection and contract negotiations.

- Technology Integration: Adopting e-procurement software and integrating it with existing ERP systems can automate many indirect procurement processes, reducing manual work, improving compliance, and enhancing efficiency.

E-procurement automates POs, invoicing, and supplier onboarding—allowing procurement teams to focus on strategy.

- Clear Procurement Policies: Establishing and communicating clear procurement policies is essential for preventing maverick spending and ensuring consistent decision-making.

Policies should outline the approved procurement processes, define spending limits, and explain the consequences of non-compliance.

Regular training and communication can help ensure that employees understand and adhere to these policies.

Best Practices for Success in Indirect Procurement:

- Develop a clear indirect procurement strategy aligned with overall business objectives.

- Implement robust spend analytics to gain visibility into spending patterns.

- Streamline procurement processes through automation and technology integration.

- Build strong relationships with key suppliers.

- Establish clear procurement policies and communicate them effectively.

- Monitor performance and track key metrics to measure progress.

Conclusion: How Moglix Middle East Helps CPOs

Moglix Middle East provides end-to-end solutions to streamline indirect procurement and enhance cost efficiency.

Our platform provides advanced spend analytics, e-procurement capabilities, and supplier management tools, enabling organizations to gain control over their indirect spend, streamline processes, and drive significant cost savings.

We help CPOs transform their indirect procurement function from a tactical operation to a strategic driver of business value.

To learn more about how Moglix Middle East can help you optimize your indirect procurement processes, mail your inquiries to emea@moglixbusiness.com

5 Ways CPOs Can Leverage AI and Automation in Indirect Procurement

5 Ways CPOs Can Leverage AI and Automation in Indirect Procurement

In today’s rapidly evolving business landscape, Chief Procurement Officers (CPOs) face relentless pressure to optimize spending, enhance efficiency, and align procurement strategies with overarching organizational objectives.

Indirect procurement—covering essential non-production goods and services—is now a prime area for AI and automation to drive efficiency and cost savings.

This article explores five impactful ways AI and automation are reshaping indirect procurement and how CPOs can effectively leverage these innovations.

1. Enhancing Spend Visibility and Analysis

One of the biggest challenges in indirect procurement is gaining a clear understanding of spending patterns.

Often, these purchases are decentralized and lack centralized oversight, leading to maverick spending, duplicated efforts, and missed opportunities for cost consolidation.

AI-powered analytics consolidate data from multiple sources, offering CPOs a real-time, holistic view of indirect procurement spending.

These tools can identify spending trends, pinpoint areas of leakage, and highlight opportunities for negotiation and cost reduction.

By gaining granular visibility into their indirect spend, CPOs can make data-driven decisions and develop targeted strategies for optimization.

2. Automating Routine Procurement Tasks

Indirect procurement often involves a significant amount of manual, repetitive tasks, such as purchase order creation, invoice processing, and supplier onboarding.

Automation can streamline these processes, freeing up procurement professionals to focus on more strategic activities.

Robotic Process Automation (RPA) can automate rule-based tasks, reducing errors, accelerating cycle times, and lowering operational costs.

AI-powered chatbots can also handle routine inquiries and provide support to internal stakeholders, further enhancing efficiency.

By automating these routine tasks, CPOs can improve productivity, reduce administrative overhead, and improve the overall efficiency of the procurement function.

3. Optimizing Supplier Management

Handling multiple suppliers is time-intensive and often inefficient without AI-driven insights.

AI can help CPOs optimize supplier relationships by providing insights into supplier performance, risk, and compliance.

AI tools assess supplier risks—financial instability, regulatory compliance, or supply chain disruptions—helping CPOs make data-driven decisions.

They can also automate supplier performance reviews and provide recommendations for supplier selection and development.

By leveraging AI for supplier management, CPOs can reduce risk, improve supplier performance, and build stronger, more strategic partnerships.

4. Driving Cost Savings Through Smart Negotiations

Optimizing supplier contracts and pricing strategies is key to reducing indirect procurement costs.

AI can empower CPOs with data-driven insights to support their negotiations.

AI-powered tools can analyze historical pricing data, market trends, and supplier information to identify optimal pricing strategies.

They can also simulate different negotiation scenarios and provide recommendations for achieving the best possible outcomes.

By leveraging AI for negotiations, CPOs can drive significant cost savings and improve their bargaining position.

5. Enabling Strategic Sourcing

AI-driven strategic sourcing identifies the most cost-effective and high-quality suppliers based on market trends and performance data.

AI can play a crucial role in this process by analyzing market data, supplier capabilities, and internal requirements to identify potential suppliers that meet the organization’s needs.

AI-powered platforms can also automate the request for proposal (RFP) process, streamlining supplier selection and reducing the time and effort required for sourcing activities.

By leveraging AI for strategic sourcing, CPOs can identify the most qualified suppliers, negotiate favorable terms, and ensure that the organization is getting the best value for its money.

Case in Point: A Global Manufacturer’s AI Transformation

A global manufacturing company implemented an AI-powered procurement platform to transform its indirect procurement processes.

The AI platform seamlessly integrated with the company’s ERP, delivering real-time spend visibility and actionable cost-saving insights.

The AI-powered analytics tools identified significant opportunities for cost consolidation and contract renegotiation.

The company also automated its purchase order process, reducing processing time by 50%.

These initiatives led to a 15% drop in indirect procurement costs and a substantial boost in operational efficiency.

Conclusion: The Future of Indirect Procurement is Intelligent

AI and automation are reshaping indirect procurement—driving efficiency, lowering costs, and reducing supplier risks.

By embracing these technologies, procurement leaders can transition from being operational managers to strategic enablers, driving value across the organization.

The future of indirect procurement is intelligent, and CPOs who embrace AI and automation will be best positioned to succeed in the increasingly competitive global marketplace.

Ready to transform your procurement function with AI and automation?

Partner with us at Moglix to unlock the full potential of smart procurement solutions. Mail your inquiries to emea@moglixbusiness.com or contact us today to get started: https://business.moglix.ae/contact-us/

The Rise of Smart Indirect Procurement: How CPOs are Redefining Cost Management

The Rise of Smart Indirect Procurement: How CPOs are Redefining Cost Management

Direct procurement, focuses on raw materials and production components, and often receives significant attention. Indirect procurement, covering essential business operations, is a largely untapped area where CPOs can unlock major cost savings and efficiency improvements.

This is where the rise of smart indirect procurement comes into play, empowering CPOs to redefine cost management and drive strategic impact.

What is Smart Indirect Procurement?

Smart indirect procurement goes beyond traditional transactional purchasing.

It’s a strategic approach that leverages technology, data analytics, and collaborative partnerships to streamline processes, gain spend visibility, and optimize costs associated with non-production related goods and services.

It’s about moving from reactive purchasing to proactive, data-driven decision-making.

Why Indirect Procurement Matters?

Indirect procurement, while often overlooked, represents a significant portion of overall organizational spending.

Key indirect procurement areas like office supplies, IT, travel, marketing, and MRO contribute significantly to operational costs.

Inefficient management of these categories can lead to inflated prices, maverick spending, and lost opportunities for cost consolidation.

Smart indirect procurement addresses these challenges, enabling CPOs to gain control over this often-fragmented spending and unlock substantial savings.

How CPOs Are Redefining Cost Management in Indirect Procurement?

CPOs are leveraging several key strategies to transform indirect procurement and drive significant cost improvements:

- Harnessing Data for Spend Analysis: Visibility is the foundation of effective cost management.

CPOs are deploying advanced analytics and spend management software to gain a comprehensive view of spending patterns across all indirect categories.

These tools provide real-time insights into who is buying what, from whom, and at what price.

This granular data allows CPOs to identify opportunities for cost savings, eliminate redundant purchases, and negotiate better pricing with suppliers.

- Adopting Automation: Manual processes, such as invoice processing, purchase order generation, and supplier onboarding, are time-consuming, error-prone, and costly.

CPOs are automating these tasks using specialized procurement platforms and e-procurement solutions.

Automation not only reduces operational costs and frees up valuable time for procurement professionals to focus on strategic activities but also minimizes errors and accelerates procurement cycle times.

- Implementing Category Management: Category management is a strategic approach to organizing procurement activities around specific categories of spend.

CPOs are implementing category management strategies to consolidate spending within key areas, such as IT, office supplies, or travel.

By centralizing procurement for these categories, organizations can leverage their buying power to negotiate better pricing and contract terms with suppliers.

It also reduces the number of suppliers and standardizes product offerings.

- Focusing on Supplier Collaboration: Smart indirect procurement recognizes the importance of strong supplier relationships.

CPOs are moving beyond transactional interactions and building strategic partnerships with key suppliers.

Collaborative relationships foster innovation, improve service levels, and unlock opportunities for cost reduction through joint initiatives, such as value engineering and continuous improvement programs.

- Leveraging AI and Predictive Analytics: Artificial intelligence (AI) and predictive analytics are transforming indirect procurement by providing CPOs with powerful tools for forecasting demand, optimizing pricing, and managing risk.

AI-powered solutions can analyze historical data, market trends, and supplier information to predict future demand for indirect goods and services.

This allows CPOs to proactively negotiate contracts, avoid stockouts, and optimize inventory levels.

Predictive analytics can also help identify potential risks in the supply chain, allowing CPOs to take proactive measures to mitigate disruptions.

Key Benefits of Smart Indirect Procurement

The adoption of smart indirect procurement strategies delivers a range of significant benefits:

- Cost Savings: By gaining spend visibility, consolidating suppliers, and negotiating better pricing, CPOs can achieve significant cost reductions in indirect procurement.

- Operational Efficiency: Automation and streamlined processes improve procurement cycle times, reduce administrative overhead, and free up procurement staff to focus on strategic initiatives.

- Risk Mitigation: Predictive analytics and enhanced supplier collaboration help CPOs identify and mitigate potential risks in the supply chain, ensuring business continuity.

- Sustainability: Smart indirect procurement enables CPOs to integrate environmental, social, and governance (ESG) criteria into procurement decisions, driving sustainability goals and promoting responsible sourcing practices.

Conclusion: The Future of Indirect Procurement

Smart indirect procurement is no longer a futuristic concept; it’s a necessity for organizations seeking to optimize spending, improve efficiency, and drive strategic value.

By embracing data-driven decision-making, automation, and collaborative partnerships, CPOs are transforming indirect procurement from a tactical function to a strategic driver of business success.

Discover how smart indirect procurement can optimize your cost management strategy. Contact us at emea@moglixbusiness.com.

2025 Procurement Outlook: P2P Digitization and the Road to Lean Supply Chains for CPOs in the Middle East

2025 Procurement Outlook: P2P Digitization and the Road to Lean Supply Chains for CPOs in the Middle East

As the Middle East continues its journey toward economic transformation, Chief Procurement Officers (CPOs) are increasingly looking to enhance their procurement operations to stay competitive. One of the most pivotal trends driving change is P2P digitization—the automation of the Procure-to-Pay (P2P) process. Transitioning to digital procurement systems has become essential for businesses seeking to streamline operations, cut costs, and achieve strategic objectives.

What is P2P Digitization?

P2P digitization refers to automating the entire procurement cycle, from purchasing requisition (PR) to purchase order (PO) and payment. Digital tools enable seamless workflows, minimizing manual intervention, improving accuracy, and boosting process efficiency. This transformation goes hand in hand with broader digital transformation in procurement, helping companies remain agile and responsive in a rapidly changing business environment.

Why P2P Digitization is the Necessity for the Middle East

Economic Diversification

The Middle East is undergoing significant economic diversification, particularly through initiatives like Saudi Vision 2030 and the UAE’s industrial strategies. These large-scale national projects drive regional efforts to reduce oil dependency and expand into technology, manufacturing, and services. As companies across various industries scale up, procurement processes must evolve to support this growth. Paper-based methods cannot keep up with the rising demand for efficiency, cost management, and transparency. P2P digitization offers a way to streamline procurement activities, allowing businesses to scale and meet the region’s ambitious economic targets while reducing manual workload and the risk of errors.

Global Supply Chain Pressures

The global supply chain landscape has been increasingly turbulent. The ongoing effects of the COVID-19 pandemic, geopolitical tensions, and fluctuations in demand have placed immense pressure on supply chains. Rising costs and disrupted operations are key concerns for procurement leaders, including CPOs in the Middle East. To navigate these challenges, organizations must adopt more agile procurement processes that can quickly adapt to changes. P2P digitization offers an effective solution by enabling real-time tracking of orders, payments, and approvals. This allows CPOs to promptly address disruptions, monitor spending, and sustain supplier relationships—key during periods of uncertainty.

Sustainability Goals

Sustainability is rapidly becoming a top priority for businesses across the Middle East. As the region seeks to position itself as a leader in sustainable practices, organizations are increasingly integrating sustainability into their procurement strategies. By leveraging Procurement automation for CPOs, companies can not only streamline operations but also track and measure their environmental impact. Digital tools empower CPOs to monitor supplier compliance, automate reporting, and ensure transparency in material sourcing. P2P digitization can also help companies consolidate orders and reduce waste, further supporting their sustainability goals.

How P2P Digitization Supports Lean Supply Chains

A lean supply chain focuses on eliminating waste, optimizing processes, and ensuring efficiency at every stage of production and delivery. P2P digitization directly supports this by:

- Streamlining Processes: Automating procurement tasks reduces unnecessary steps, allowing CPOs to focus on strategic decision-making. By eliminating manual paperwork and approvals, procurement teams can process orders faster and with fewer errors.

- Improving Supplier Collaboration: Digital tools improve communication with suppliers by providing real-time updates and enabling automatic notifications. This strengthens supplier relationships, leading to faster response times, better negotiation opportunities, and stronger partnerships.

- Enhancing Data Visibility: With real-time tracking and centralized data, CPOs can better monitor procurement activities, supplier performance, and expenditure. This visibility allows for more informed decision-making and proactive measures to avoid delays, manage risk, and ensure that supply chains are operating at their most efficiently.

- Reducing Costs: By digitizing the P2P cycle, organizations can cut down on paper-based processes, eliminate duplicate entries, and reduce administrative overhead.

Automated workflows reduce human error, driving cost savings and enhanced profitability. Additionally, businesses can negotiate better terms with suppliers due to improved transparency.

Conclusion: The Path to 2025

Looking ahead to 2025, P2P digitization will remain central to effective procurement strategies for CPOs in the Middle East. With economic diversification initiatives, global supply chain pressures, and sustainability goals shaping the business landscape, it’s clear that P2P automation is no longer optional—it’s essential. Explore our full whitepaper to understand how P2P digitization can transform procurement and advance lean supply chain objectives.

For further inquiries, feel free to reach out to us at emea@moglixbusiness.com.

2025 Procurement Outlook: How Much Does PR-to-PO Digitization Matter to CPOs?

2025 Procurement Outlook: How Much Does PR-to-PO Digitization Matter to CPOs?

In today’s dynamic business environment, Chief Procurement Officers (CPOs) are constantly exploring strategies to enhance efficiency, lower costs, and foster innovation. One key development in this pursuit is PR-to-PO digitization, a transformation that moves procurement processes from paper-based, manual systems to automated, digital workflows. But why does this shift matter so much to CPOs? Let’s take a closer look.

What is PR-to-PO Digitization?

PR-to-PO digitization refers to the seamless integration of systems that connect Purchase Requisitions (PR) to Purchase Orders (PO). This process removes manual interventions by automating tasks like request creation, approval workflows, order placements, and supplier communications. It’s all about streamlining the procurement cycle, making it faster, more accurate, and more cost-effective.

Why PR-to-PO Digitization Matters?

1. Enhanced Process Efficiency

One of the most significant benefits of PR-to-PO digitization is improved efficiency. Traditional procurement workflows can be time-consuming and prone to errors. Automating routine tasks, like approvals and data entry, allows procurement teams to save significant time on repetitive processes. Automation allows for faster turnaround times, better resource allocation, and smoother operations. This is critical as organizations strive to stay competitive and responsive to changing market dynamics.

2. Improved Accuracy

Manual procurement processes often lead to human errors, such as incorrect data entry, delayed approvals, or mismatched orders. These mistakes can result in costly rework, delays, and strained supplier relationships. PR-to-PO digitization resolves these issues by enabling single-point data entry that is automatically propagated throughout the procurement cycle. With built-in checks and validation rules, digitization enhances data accuracy, minimizing the risk of mistakes and ensuring compliance with organizational standards.

3. Real-Time Visibility

With PR-to-PO digitization, CPOs gain real-time visibility into procurement activities. They can track purchase requisitions, approvals, and purchase orders at every step of the process, all in one centralized system. This enhanced visibility enables procurement teams to quickly identify bottlenecks, address delays, and ensure that orders are being processed as expected. Additionally, it enables CPOs to track supplier performance, promptly address issues, and ensure seamless procurement operations.

4. Cost Savings

Cost-saving is a top priority for CPOs, and PR-to-PO digitization plays a significant role in achieving this goal. By automating processes, reducing errors, and improving supplier collaboration, organizations can minimize costs associated with procurement. Digitization also allows for better contract management, price tracking, and order consolidation, which can lead to volume discounts and improved terms with suppliers. Over time, these efficiencies translate into substantial savings for the organization.

5. Better Supplier Relationships

Supplier relationships are crucial for procurement success, and PR-to-PO digitization helps improve communication and collaboration between buyers and suppliers. Digital systems can enable real-time updates, automatic notifications, and more transparent processes, leading to smoother transactions and fewer misunderstandings. Suppliers gain access to portals that enable order tracking, invoice management, and swift issue resolution. This fosters stronger, more reliable partnerships and creates opportunities for joint growth and innovation.

The Impact of PR-to-PO Digitization on CPOs

For CPOs, the digital transformation of procurement is not just about adopting new technology—it’s a strategic enabler that aligns with broader organizational goals. PR-to-PO digitization empowers CPOs to:

Drive Lean Procurement

Automating processes and eliminating inefficiencies make PR-to-PO digitization a cornerstone of lean procurement strategies. CPOs can streamline operations, reduce overhead costs, and focus on value-added activities. This alignment with lean principles helps procurement teams achieve operational excellence and ensures resources are utilized efficiently.

Enhance Decision-Making

Access to real-time data and analytics allows CPOs to make more informed and proactive decisions. They can quickly analyze procurement performance, identify trends, and make adjustments as needed. This agility is crucial in today’s fast-paced business environment, where quick decision-making can lead to a competitive advantage.

Lead Digital Transformation

PR-to-PO digitization positions procurement as a leader in digital transformation. Adopting advanced technologies enables CPOs to spark innovation across the procurement function and beyond. It shows that procurement is not just a support function but a strategic driver of change and modernization.

Looking Ahead to 2025

As organizations continue to embrace digital transformation, PR-to-PO digitization will remain a key priority for CPOs. Streamlining procurement, enhancing efficiency, and reducing costs empower CPOs to drive organizational growth and success well into 2025 and beyond. To gain deeper insights into the future of procurement, including lessons learned from 2024, explore our full whitepaper. For further inquiries, feel free to reach out to us at emea@moglixbusiness.com.

2025 Procurement Outlook: How Much Visibility Do CPOs Have into the Supply Chain?

2025 Procurement Outlook: How Much Visibility Do CPOs Have into the Supply Chain?

Supply chain visibility is essential in today’s interconnected world, where disruptions can significantly impact industries. For Chief Procurement Officers (CPOs), having a clear view of supply chain operations is not just a competitive advantage—it’s essential for reducing inefficiencies, protecting margins, and navigating uncertainty in global markets in 2025.

Unlocking Supply Chain Efficiency: The Need for a Holistic View

Supply chains are the backbone of global business. However, inefficiencies caused by a lack of transparency hinder decision-making and increase operational costs. To remain competitive in 2025, CPOs must adopt a comprehensive approach to gain end-to-end visibility and optimize their supply chains.

1. Asymmetry of Information: The Silent Disruptor

The fragmented flow of information between manufacturers, suppliers, and retailers creates significant inefficiencies. Without unified visibility, predicting demand patterns becomes difficult, often resulting in avoidable disruptions. Investing in digital platforms that connect all supply chain stakeholders in real-time can eliminate these gaps. With tools like cloud-based systems, businesses can achieve seamless communication and minimize disruptions caused by information asymmetry.

2. The Cost of Opacity: Slow Decision-Making

Opaque supply chains result in decisions made without a comprehensive understanding of key situations. This lack of clarity slows transactions, decreases business agility, and contributes to broader economic challenges, such as reduced productivity.

Advanced technologies, including real-time analytics and AI, can provide actionable insights that enhance decision-making speed, improve operational efficiency, and help businesses thrive in competitive markets.

3. Variability in the Upstream: The Bullwhip Effect

Small upstream disruptions often result in significant downstream effects.

Delays, cost overruns, and service level agreement (SLA) breaches are all consequences of this variability. By enhancing upstream visibility, CPOs can proactively address potential issues, stabilize supply chain operations, and maintain smooth downstream workflows.

4. Waste: The Hidden Cost of Invisibility

Without proper visibility, inefficiencies such as overstocking, understocking, and wasted resources become prevalent. This directly impacts operational costs and limits profitability. Using advanced technology to monitor inventory levels and supplier performance helps businesses reduce waste, control costs, and continuously improve supply chain operations.

5. Navigating the “Now” to Reach the “Next”

CPOs must understand the current state of their supply chain to plan for future growth and improvements. Visibility into existing operations allows for agile decision-making, cost optimization, and the flexibility to adapt to rapidly changing market conditions. By using predictive analytics and other data-driven technologies, organizations can transition from reactive to proactive strategies, ensuring sustained growth and resilience.

6. Margin Protection: The Key to Staying Competitive

Without real-time insights into supply chain activities, businesses struggle to manage costs and mitigate risks, leaving margins exposed. In an environment where margins are already under pressure, this lack of visibility can be detrimental. Implementing technologies that offer dynamic tracking and analytics helps organizations safeguard profitability, reduce risks, and maintain their competitive edge.

7. Process and Technology: The Dual Approach

To resolve supply chain visibility challenges, businesses need a dual approach. Streamlined processes improve efficiency, while advanced technologies such as AI, machine learning, and real-time analytics enable informed decision-making. This combination ensures higher ROI, increased efficiency, and long-term sustainability in supply chain management.

Conclusion

The future of supply chain visibility lies in adopting technology-driven solutions and robust processes. As CPOs plan for 2025, aligning operations with a long-term transparency strategy is critical to addressing challenges, safeguarding margins, and reducing costs.

For further insights and a comprehensive outlook for 2025, access our full whitepaper. Mail your inquiries to emea@moglixbusiness.com.

Voice of Procurement: Insights and Analysis on Supply Chain Strategies

Voice of Procurement: Insights and Analysis on Supply Chain Strategies

Volume 2

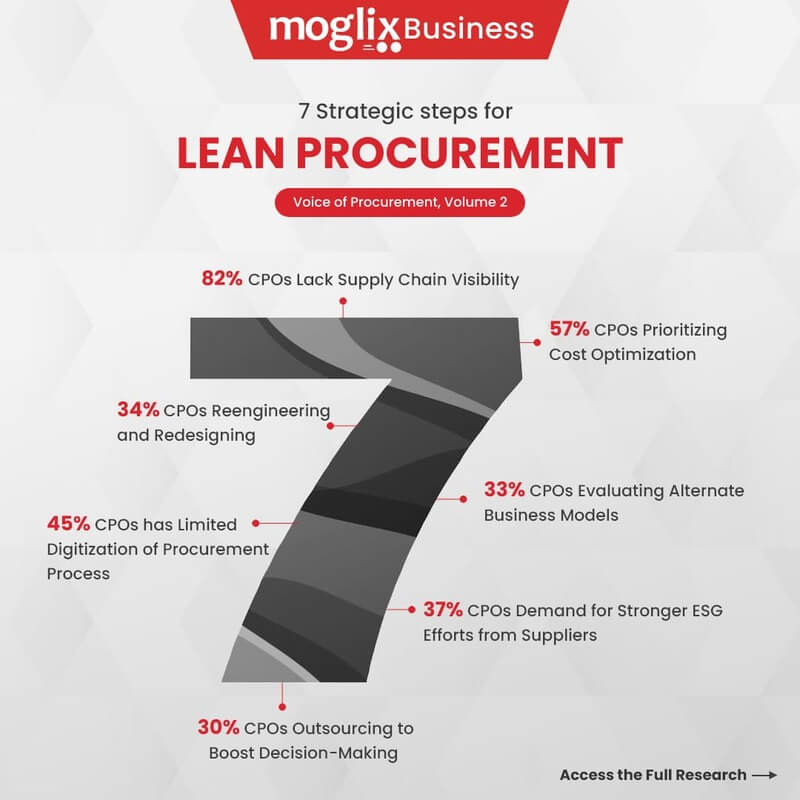

Decoding the Shift Towards Lean Procurement

What Makes Volume 2 of Voice of Procurement Stand Out?

- 7 chapter with unique insights for procurement journey

- What you can do to transform your procurement supply chain

- Best practices for procurement teams in 2024 and what’s next in 2025

- Recommendations & case studies for you to get started on lean procurement

To access full whitepaper and the latest research insights about procurement, become a client.

The UAE has got a vision to digitize its business process under UAE Digital Government Strategy 2025.

Every day, CPOs and their teams from more than 200+ manufacturing firms in UAE and across the world use Moglix Business’s procure-to-pay operating system to continuously enhance performance. Contact a Moglix Business procurement expert to learn how you may begin the process of continual cost improvement.

What is included in the Voice of Procurement’s second volume?

The Voice of Procurement’s volume 2 offers seven insights into how procurement CXOs responded to seven important trends in 2024 as opposed to 2023, and what course of action they are likely to adopt in 2025.

Each of these chapters includes:

- A synopsis of the chapter that highlights the trend

- Key lessons for CXOs around supply chain and procurement

- User suggestions for teams and procurement leaders

- Practical frameworks for procurement CXOs to begin implementing continuous improvement

From Continuous Improvement to Continuous Cost Optimization: The Rise of Lean Procurement

The science of doing more with less is catching up with the community of procurement professionals who serve as supply chain managers like never before, addressing everything from work in process, inventory levels, and time to expenses.

Engineers are responsible for creating products or building infrastructure projects. Enabling its manufacture or construction at the lowest possible cost is the responsibility of the procurement team.

However, it takes more than merely negotiating with suppliers to find the best price to achieve continual cost optimization throughout months, financial quarters, and financial years. It requires procurement that is lean.

Observations on the Whitepaper’s Research

In 2024, we conducted a second survey with 130 participants from a wide range of manufacturing industry verticals. The survey asked the same seven questions as the previous year to gauge the procurement community’s changing viewpoints.

Seven conclusions, analyses, and insights on topics ranging from a comprehensive supply chain perspective, ESG compliance, digital procurement & supply chain transformation, and procurement outsourcing were obtained at the conclusion of the data collection and analysis activity.

The Whitepaper’s audience

The Indian manufacturing supply chain ecosystem’s procurement and supply chain leaders are the target audience for this whitepaper. The following industry verticals and sub-sectors’ combined responses and priorities are reflected in the trends we have observed for procurement and digital supply chain transformation:

- Automobile

- Infrastructure EPC

- Electrical Switchgear

- Tyres

- Metals & Mining (Non-Ferrous and Iron & Steel)

- Wires & Cables

- Textiles

- Pharma

- Chemical

- Renewable Energy (Solar PV, Hybrid)

- Consumer Electronics

- الإسمنت

- السلع الاستهلاكية سريعة الحركة

- Footwear

- Real Estate

Why Is It Important for CPOs to Understand Procurement Compliance

Why Is It Important for CPOs to Understand Procurement Compliance

Procurement compliance in the UAE is a critical priority for Chief Procurement Officers (CPOs) tasked with managing supply chains and fostering vendor relations.

Amid rapidly evolving regulations under the UAE Government (UAE Gov), non-compliance can result in hefty fines, legal disputes, and harm to organizational reputation.

Understanding procurement compliance enables CPOs to align their practices with the law, ensuring efficiency and transparency while mitigating risks.

The Landscape of Procurement Compliance in the UAE

The UAE’s regulatory framework for procurement is structured to uphold ethical practices, drive economic growth and ensure transparency across supply chains.

CPOs must be familiar with several compliance aspects, including:

- Federal and Emirate-Level Laws:

Procurement laws in the UAE operate at both federal and emirate levels, necessitating a comprehensive understanding of regional nuances alongside overarching directives. - Vendor Prequalification:

Regulations mandate rigorous vetting processes to ensure suppliers meet quality, ethical, and financial standards.

- Government Initiatives:

Programs like Make It in the Emirates emphasize local sourcing and sustainable procurement, which CPOs must incorporate into their strategies.

- E-Procurement Adoption:

The UAE Gov is encouraging digital transformation in procurement, pushing businesses to adopt e-procurement solutions for better traceability and efficiency.

Why do CPOs need to Prioritize Procurement Compliance?

Risk Mitigation

Non-compliance exposes organizations to:

- Legal Penalties: Violations of procurement laws can lead to fines or project delays.

- Reputational Damage: Mismanagement can harm trust with stakeholders and the UAE Gov.

Cost Efficiency

Compliance with procurement regulations streamlines budgeting, eliminates unnecessary penalties, and enhances overall operational efficiency.

Enhancing Transparency and Trust

A strong focus on procurement compliance reflects ethical practices, and improving relationships with vendors, regulators, and investors.

Aligning with Strategic Goals

Procurement compliance supports broader organizational objectives, including sustainability, innovation, and local economic development initiatives championed by the UAE Gov

Key Compliance Challenges and How to Address Them

Staying Updated on Regulatory Changes

- Challenge: Frequent changes to procurement laws can be challenging to track and implement.

- Solution: Form a specialized compliance team or deploy AI-enabled procurement tools to monitor updates and ensure timely implementation.

Complex Approval Processes

- Challenge: Prolonged vendor approval and contract management timelines.

- Solution: Utilize e-procurement platforms to streamline workflows and minimize delays.

Diverse Stakeholder Expectations

- Challenge: Balancing regulatory compliance with internal stakeholder demands.

- Solution: Foster a culture of compliance by conducting regular training for procurement teams.

Case Study: Successful Procurement Compliance in the UAE

Problem:

A multinational corporation in the UAE encountered significant hurdles in vendor prequalification and audit compliance. They experienced delays in project execution and incurred penalties due to incomplete documentation.

Solution:

The company adopted a procurement solution tailored to UAE compliance needs. Key actions included:

- Automating vendor evaluations.

- Standardizing documentation processes to meet UAE Gov requirements.

- Conducting regular compliance audits using digital tools.

Outcome:

The organization achieved full compliance, minimized project delays by 30%, and enhanced its rapport with key government stakeholders.

The Role of Technology in Procurement Compliance

Digital tools are transforming procurement compliance in the UAE. E-procurement platforms provide:

- Automated Tracking: Monitor vendor performance and regulatory adherence in real time.

- Data Insights: Gain actionable intelligence to optimize procurement strategies.

- Audit Readiness: Ensure all documentation is readily available for regulatory reviews.

Integrating such digital tools not only streamlines compliance but also significantly boosts overall operational efficiency.

Conclusion

For CPOs, procurement compliance in the UAE extends beyond avoiding penalties; it is about aligning with government initiatives, embedding ethical practices, and achieving strategic objectives.

By staying informed on regulatory changes, leveraging technology, and fostering a culture of compliance, procurement leaders can navigate the complexities of the UAE’s regulatory environment effectively.

Investing in procurement solutions customized for the UAE market is pivotal to achieving long-term success and ensuring seamless operations in this dynamic region.

From Crisis to Opportunity: How CPOs Can Turn Supply Chain Problems into Strategic Wins

From Crisis to Opportunity: How CPOs Can Turn Supply Chain Problems into Strategic Wins

Chief Procurement Officers (CPOs) are increasingly grappling with supply chain challenges, including material shortages, transportation delays, and surges in demand, which can disrupt operations.

However, every challenge presents an opportunity for growth. By adopting a strategic approach and leveraging technologies like procurement tools and automation, CPOs can create resilient and efficient supply chains.

Establishing a Base for Supply Chain Operations

To effectively transform challenges into opportunities, Chief Procurement Officers (CPOs) must prioritize strengthening supplier relationships and ensuring the accuracy of decision-critical data.

- The Role of Data in Achieving Supply Chain Success

Accurate supplier information forms the backbone of procurement processes.

Inaccuracies or duplications can lead to errors, production delays, and compliance challenges.

Having accurate data that’s easily accessible enhances the ability to make informed decisions and cultivate positive relationships with suppliers.

- Supplier Experience: The Virtuous Cycle

Reliable data is the cornerstone of a positive supplier experience.

Clear communication and seamless processes encourage suppliers to reciprocate with accurate information, fostering mutual trust and operational efficiency.

Conversely, poor data and engagement result in delays, miscommunication, and strained relationships.

10 Actions for CPOs to overcome challenges and turn them into opportunities

1.Understand the Risks: Identify potential risks such as supply disruptions, supplier instability, and rising costs.

Leverage tools like digital twins to analyze and anticipate these challenges.

For example, a European utility tracks material costs and inflation data to prevent supply disruptions.

2. Gain Real-Time Insights: Establish a resilience dashboard to track real-time updates on supply disruptions, pricing trends, and inventory levels for proactive management.

For instance, an automotive company monitors thousands of components using automated data systems, helping them handle market changes efficiently.

3. Update Procurement Strategies: Regularly revise purchasing plans to address changes in labor and logistics costs.

Collaborate with suppliers to innovate, reduce waste, and improve sustainability.

4. Improve Risk Management: Upgrade systems to predict shortages, track sales risks, and assess supplier reliability.

For example, companies use predictive tools to stock up inventory before issues arise.

5. Streamline Operations: Partner with teams across your organization to simplify processes, reduce demand complexity, and work more effectively with suppliers.

These improvements can give your company a competitive edge.

6. Optimize Energy Use: Implement strategies to achieve both immediate and long-term energy savings.

For example, a materials company reduced costs by 20% and CO2 emissions by 30% by refining its energy sourcing approach.

7. Align Costs and Pricing: Work with sales teams to adjust customer pricing based on market and cost trends.

A packaged foods company offset inflation by finding new suppliers and managing raw material inventories, which helped them retain customers and minimize losses.

8. Redesign Products: Reduce dependency on scarce materials by changing product designs.

For example, a consumer goods company used data to find alternatives that didn’t affect customer satisfaction, helping them avoid stockouts and price spikes.

9. Set Up a Control Tower: Create a central team to monitor markets, manage risks, and act quickly.

For example, a materials producer used an automated dashboard to negotiate better deals with suppliers during economic uncertainty.

10. Build a Skilled Team: Invest in talent with expertise in data analysis and risk management. Foster career growth opportunities to attract and retain top professionals, ensuring sustained resilience.

By understanding risks, optimizing processes, and working closely with suppliers and internal teams, CPOs can control costs, improve services, and create a more resilient supply chain.

How Moglix Can Help?

Moglix empowers CPOs to revolutionize their supply chains with comprehensive procurement solutions.

From procurement automation to supplier data management, our platform simplifies complexity and enhances operational efficiency. With Moglix, you can:

- Centralize and clean supplier data.

- Automate procurement processes for efficiency and cost savings.

- Gain real-time visibility into your supply chain for better decision-making.

In a Nutshell

CPOs have the power to transform today’s supply chain challenges into tomorrow’s competitive advantages.

By leveraging procurement technology, fostering better supplier relationships, and embracing data-driven strategies.

CPOs can lay a strong foundation and lead their organizations toward resilience and growth.

Now is the time to act. Armed with the right tools and strategies, CPOs can turn every supply chain challenge into a strategic advantage. For inquiries, please reach out to us at emea@moglixbusiness.com .